Although fall protection is mandatory in many workplaces, it is often overlooked and the risk of falling is taken lightly. However, it should not be underestimated because it is the third most common cause of fatal accidents at work. Go through the simple numbers with us: the reaction time of a person to an unexpected event is approximately two seconds. During this time, a person falls almost 20 meters and reaches a speed of 71 km/h. In short, it only takes a little hesitation or a moment of carelessness for an accident to happen. Read how together we can significantly reduce the risk of falling.

When is fall protection needed?

Fall protection is required when there is a risk of a worker falling from a height, either due to elevations or depressions. OSHA requires that fall protection be provided at heights of four feet in general industrial workplaces, five feet in shipyards, six feet in the construction industry, and eight feet in ground floor operations. . In addition, OSHA requires that fall protection be provided when working over water or hazardous materials, equipment, and machinery, regardless of the distance from the fall.

It’s good to know

An important part of the overall system of using protective equipment against falling is the evacuation and rescue plan. Every worker and responsible person who supervises work at height must be familiar with this plan.

Follow the principles of safe use of fall protection equipment and the rules for working at height. Before each use of fall protection devices, check that they are in good condition.

No product must show signs of damage or defects that affect its function.

Follow the manufacturer’s instructions for use when using fall protection equipment.

Each of the mentioned means is subject to regular revision control, every 12 months from the first use. The shelf life of these products is determined by the manufacturer in the instructions for use.

Basics of working at height

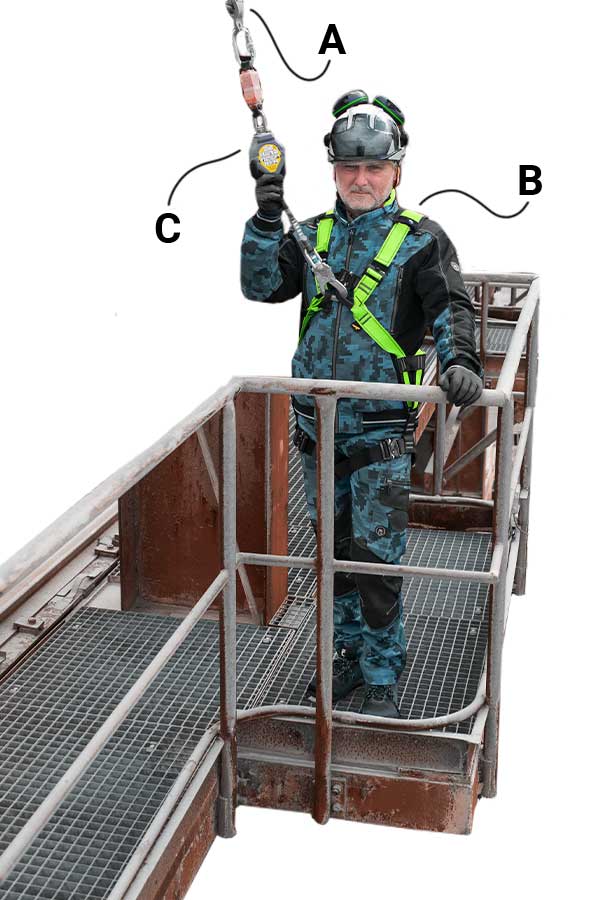

The basic components of fall protection are described by the ABC system:

A: Anchoring

B: Body (belt)

C: Relationship

The system just works, as soon as one part is missing, it cannot be used.

A – Anchoring point / anchoring equipment

The anchoring point can be a profile beam, scaffolding, beam or other constructive point. Installed anchor points are usually marked with a distinctive color. Do not use uncertified anchor points. Never use places of unknown or questionable load capacity for anchoring!

Anchoring devices can be installed permanently (horizontal or vertical cable or rail systems, permanently installed anchor points) or only temporarily (anchor loops or cables, metal supports, scaffold eyes, transfer belt systems, metal clamps, etc.).

B – Body belt

A full body restraint harness is used to prevent the risk of falling, for a work position or for work suspended from a rope.

All our harnesses meet European fall arrest standards. They are distinguished by other added functions or elements that increase the comfort of use, such as quick-release buckles or belt padding.

The positioning belt serves to prevent entry into places where there is a risk of falling. However, it does not replace a seat belt.

C – Connecting devices (rope with shock absorber, self-retracting device or positioning means)

They are used as an intermediate connection between the worker’s restraint belt and the anchoring device. This is, for example, a fall arrester with a rope or a retractable fall arrester.

There are two types of fasteners:

safety systems – fall restraint systems protect workers from potential fall hazards by limiting their proximity. These systems eliminate the possibility of falling because they tether workers so that they cannot physically fall from any distance. . Fall protection devices are not intended to position or hold you in place so that you can work hands-free.

fall protection reduces the consequences of a fall. Fall arrest systems differ from fall protection systems in that they protect you when you are already in the process of falling.